、 Basic parameters:

Voltage: 380V50Hz

- Equipment power; 9.5KW

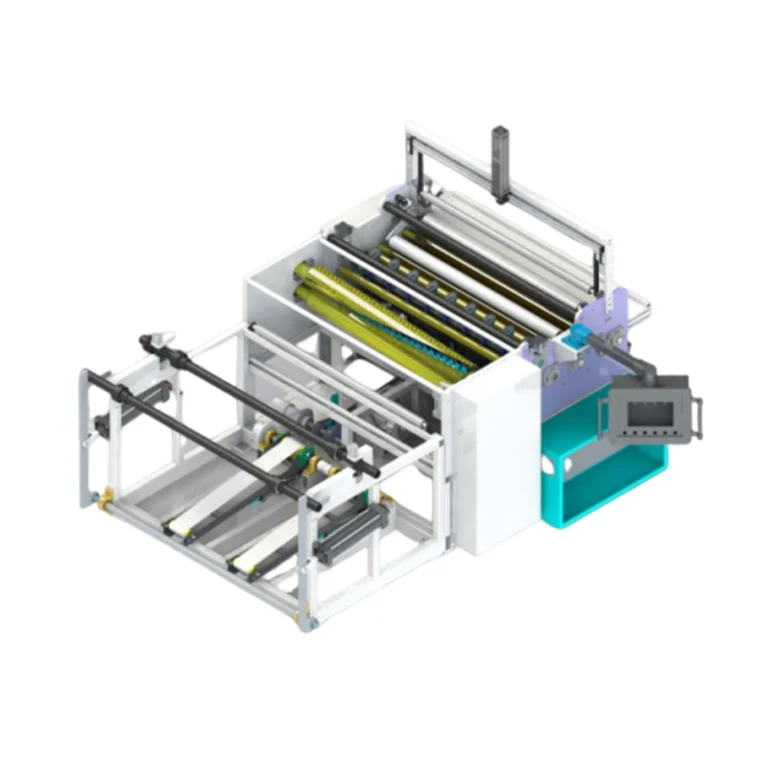

3 Equipment specifications; The first section is 1051MM long, excluding land price. The wheel height is 1878MM and the width is 2180MM

Section 2; 600mm in length, 1091MM in height without foundation wheels, 1870MM in width

Section 3; 1210MM in length, excluding foundation wheels, 1075MM in height, and 1935MM in width - Equipment weight; About 5 (T)

- Electronic control; Adopting Leisai PLC control

- Motor; Lei Sai (China) servo 2 sets 4.4KW

- Air pressure: 0.8pa

- Screen; Leisai 7-inch touch screen

- Liquid addition system; Liquid addition and automatic liquid return

- The maximum width of the raw material gate is 1200mm

- The counting method can be set to odd or even on the touch screen

- Design speed; 200 meters per minute

- Production speed; 185 meters per minute

- Slicing speed; Standard length 150MM/500-700 pieces/minute (depending on the material)

- Cutting device mechanism: using pneumatic up and down and left and right disengagement methods

- Roll diameter; Maximum winding diameter 120MM

- dashed line length: 110MM-250MM

- Loading method; Pneumatic lifting raw materials

- Cutting blade device; 10 sets

- Tension control; Using an infinite speed regulator to control tension

- dashed line device; Independent servo control, pneumatic control can cut dashed lines and non cut dashed lines

22, rewinding mechanism; One raw material stick is in operation, and the other is on standby above, with manual control of the drop rod - Before rewinding, manually press the button to blow air

- Auxiliary rewinding pneumatic pressure roller mechanism

- The dotted dots are spaced 6MM apart and 1MM wide (customized according to customer requirements)

- Random accessory list:

| Serial Number | Name | Random Accessories |

| 1 | Knife on the dotted line | 4 pieces |

| 2 | Dotted bottom knife (without drilling) | 2 pieces |

| 3 | Upper slitting knife | 10 pieces, bottom blade 10 pieces (excluding those installed on the machine) |

| 4 | Winding rod | 3 pieces including machine (including on machine) |

| Raw material stick | 2 pieces including machine (including on machine) | |

| 5 | Edge trimming pneumatic receiver | 2 (already installed on the machine) |

| 6 | Trimming pipe | 2 items (already installed on the machine) |

- Electrical Control Configuration List:

| Number | Product Name | Brand | Specification, Model |

| 1 | Main controller | Leisai | MC508CS |

| 2 | Input extension | Leisai | PM-1600 |

| 3 | Output extension | Leisai | PM-0016-N |

| 4 | 7 “touch screen | Leisai | LT207E |

| 5 | Communication line | Leisai | 3 meters |

| 6 | Servo-drive | Leisai | L6N-4400T |

| 7 | Servo motor | Leisai | ACM2M-1844T |

| 8 | Servo power line | Leisai | 5 meters |

| 9 | Servo rotary knitting line | Leisai | 3 meters |

| 10 | Servo fiber optic cable | Customized | EtherCAT cable 30cm yellow |

| 11 | Servo fiber optic cable | Customized | EtherCAT cable 100cm yellow |

| 12 | Power protector | Wind vane | FXBGQ-4X |

| 13 | Level switch sink | Customized | 0.2 meter single ball sink |

| 14 | Switch power supply | DELTA | PMT24V150W |

| 15 | Relay base | HONGFA | Two-way |

| 16 | Intermediate relay | ABB | CR-MX024DC2L |

| 17 | Proximity switch | RIKO | PCS-1205N |

| 18 | Photoelectric switch | Mote | E3Z-D61 |

| 19 | Circuit breaker | LS | BKN 3P 60A |

| 20 | Circuit breaker | LS | BKN 3P 20A |

| 21 | Circuit Breaker | LS | BKN 3P 10A |

| 22 | Circuit Breaker | LS | BKN 1P 10A |

| 23 | Contactor | ABB | AX25-3210 |

| 24 | Contactor | ABB | AX25-0910 |

| 25 | Hot relay | ABB | AU-9A |

| 26 | Button box | KND | 3 holes |

| 27 | Start button | KND | BWB3361 |

| 28 | Stop button | KND | BA42 |

| 29 | Flat head button | KND | BA31 |

| 30 | Select button | KND | BD33 |

| 31 | Emergency stop button | KND | BS542 |

| 32 | Indicator light | KND | 22D/S (green) 24V |

| 33 | Buzzer | KND | 22D/S (red) 24V |

| 34 | Three segment indicator light | NZ | LTA-205W 24V |

| 35 | Cooling fan | Customized | 120X120 with cover |