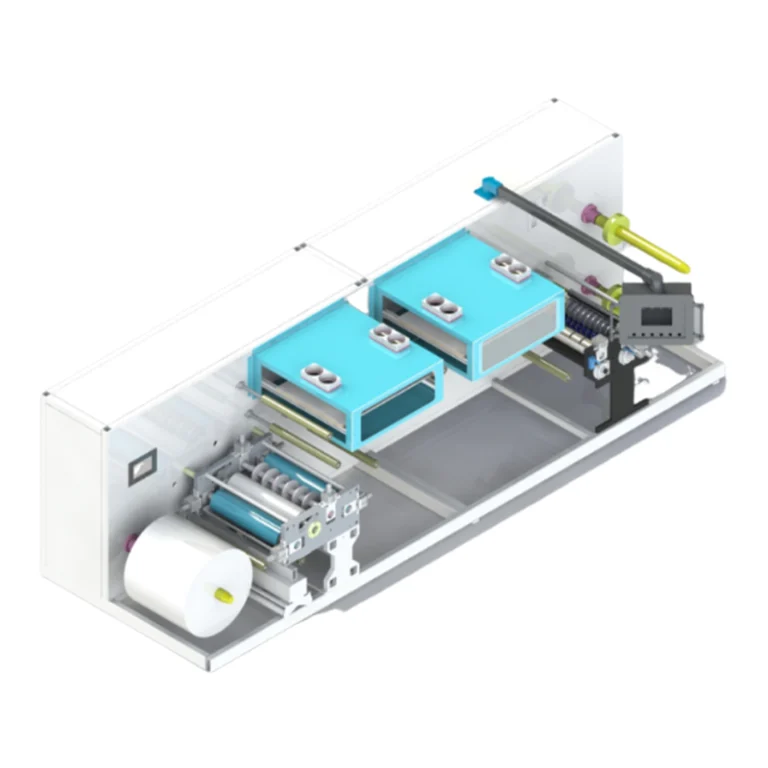

Basic parameters:

- Net weight of the machine: around 3T

- Voltage: 380V 50HZ

- Power: around 8KW

- Overall mechanical dimensions: length 3950MM * width 1490MM * height 1705MM

- Design speed: 40 meters/minute

- Production speed: 20-35 meters per minute (speed determined based on the dryness of the glue)

- Glue width: 10MM, with a single-side cutting of 5MM after gluing. (Customizable according to customer requirements)

- Number of gluing wheels: 6, each with a width of 10MM (customizable according to customer requirements)

- Control mechanism: A swing-arm type operation screen is adopted, which can be moved for convenient operation.

- Touch screen: Delta (Taiwan) 7-inch

- Gluing mechanism: This mechanism consists of a glue passing wheel, a stainless steel mesh wheel, and a transfer glue wheel. It operates using a servo motor paired with an RV reduction gear mechanism. During the stopping process, the mechanism will automatically operate to ensure that the glue inside does not dry out or become viscous. The thickness of the glue applied and the tension can be controlled. Different materials have different weights, and the tension varies accordingly. These adjustments can be made on the touch screen.

- Deviation correction: This mechanism is designed to control the deviation correction position of raw materials, allowing for both manual and automatic adjustments. It can regulate the fixed positions of gluing and cutting, ensuring that the positions do not deviate excessively and will be automatically corrected.

- Raw material roller: The position of the raw material is fixed by expanding with an air shaft. The inner diameter of the paper core is 75 and the outer diameter is 90. The tension control of the raw material unwind is achieved through magnetic powder braking.

- Oven mechanism: This mechanism controls the drying process after the product is coated with glue, ensuring that the glue is dry by the time of cutting

- Traction and Cutting Mechanism: This mechanism controls the process of drawing materials from the oven and then slitting them. The cutting width is adjustable. The equipment is equipped with 11 slitting knives and 11 bottom knives, which are made of high-speed steel.

- Temperature control zone: This zone is equipped with four temperature control meters, which are used to regulate the temperature inside the oven.

- Rewinding mechanism: This mechanism employs a servo motor to control the rewinding process, ensuring the tension and tightness of the winding. It also utilizes an air-expansion differential shaft to control the winding, thereby ensuring the tightness and uniformity of each roll.

- This equipment adopts the control system from Delta (Taiwan), a renowned brand in electrical equipment, and utilizes servo motors to control operational power, thereby achieving superior operational efficiency and stability

- The rewinder can be operated in both upper and lower sections simultaneously, and it can also be selectively controlled to close and open individually.

- Water Bucket: A 200KG bucket made of 304 stainless steel, equipped with a stirring function, and utilizing a food-grade pneumatic pump to control the dispensing of glue liquid.

- Electrical configuration list::

| Product Name | Brand | Specification and Model |

| Main controller | Delta | DVP40ES200TE |

| Touch screen 7-inch | Delta | DOP107DV |

| Servo motor | Delta | ECMA-E11310RS |

| Servo drive | Delta | ASD-A2-1021-L |

| Motor power cable | Delta | ASD-A2-EPW1003 |

| Motor encoder cable | Delta | ASD-A2-EN1003 |

| Servo motor | Delta | ECMA-E11315RS |

| Servo driver | Delta | ASD-A2-1521-L |

| Motor power cable | Delta | ASD-A2-EPW1003 |

| Motor encoder cable | Delta | ASD-A2-EN1003 |

| Photoelectric switch | Mote | E3F-DM18 |

| Linear displacement sensor | Customization | KTC-500 |

| Temperature control meter | Yudian | AI207 |

| Solid-state relay | Yangming | SSR-40DA |

| Temperature probe | Customization | K型 20CM 3米 |

| Air circuit breaker | LG | 3P C63 |

| Air circuit breaker | LG | 3P C16 |

| Air circuit breaker | LG | 2P C20 |

| Air circuit breaker | LG | 1P C10 |

| Relay base | HONGFA | Two-way |

| Intermediate relay | ABB | CR-MX024DC2L |

| AC contactor | Schneider | LC1-D3210M5N |

| Illuminated button | Konada | BWB3361 |

| Flat-headed button | Konada | BA42 |

| Flat-headed button | Konada | BA12561 |

| Key switch | Konada | BG21 |

| Emergency stop button | Konada | BS542 |

| Button box | Konada | one-hole switch box |

| Three-segment indicator light | Customization | LTA-205W 24V |

| Exhaust fan | Customization | 120X120 |

| Fan guard | Customization | Small black mesh |

| Power protector | Wind vane | FXBGQ-4X |

| Switching power supply | Delta | PMT24V350W |

| Terminal block | Changde | CBD-10 |