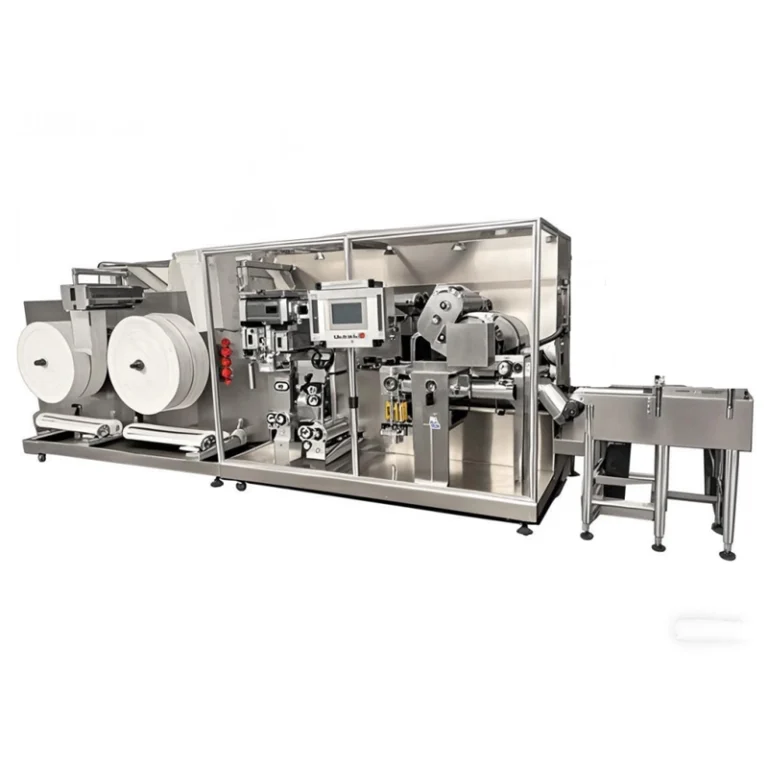

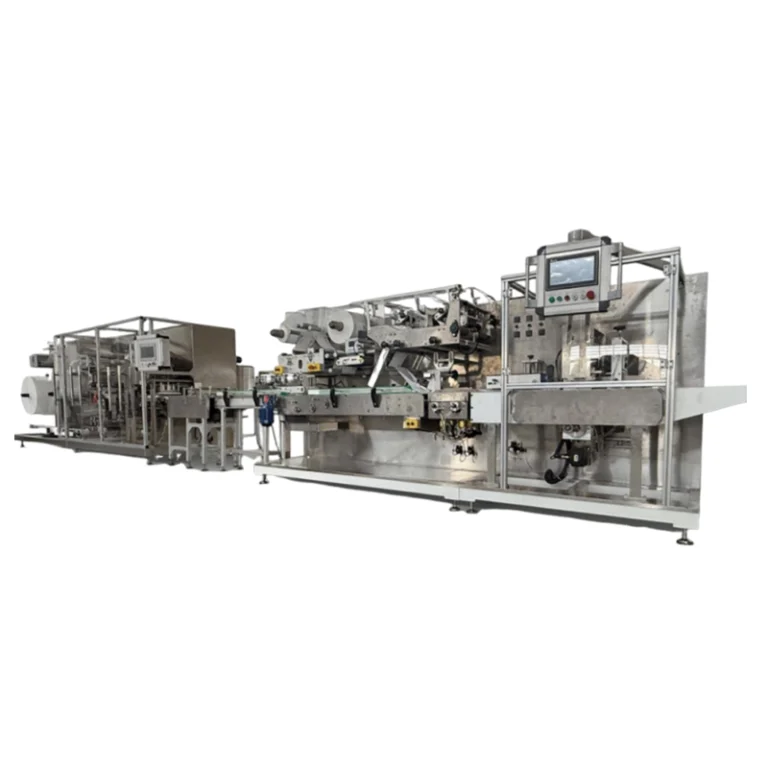

Automatic Unwinding of Nonwoven Fabric → Automatic Splicing → Constant Tension Control → Sub-width Folding → Traction and Conveying → Quantitative Humidification & Cutting → Folding in Half → Stacking & Counting → Double-Row Folding Output → Flattening & Conveying → Automatic Merging of Two Lanes → Film Unwinding of Automatic Packaging Machine → Automatic Hole Punching → Automatic Labeling (Dual Labeling) → Heat Sealing & Cutting (Back Sealing + Horizontal Sealing) → Automatic Corner Insertion → Product Air Pressurization → Finished Product Output

I. Equipment Parameters

Production Speed: Maximum speed 100 packs/min or 1200 sheets/min; stable speed 95-100 packs/min for 10 sheets/pack; stable speed 55-60 packs/min for 20 sheets/pack

Raw Material Dimensions (mm): Single roll dimension (130-210)×2×φ1200mm (web width×layers×diameter); unfolded dimension (mm): (130-210)×(140-210) (width×length); folded dimension (mm): (50-100)×(70-105) (width×length, folded in half)

Liquid Adding Ratio: 2.5-5 times (weight of dry nonwoven fabric × ratio)

Folding Method: Z-shape, N-shape, C-shape

Applicable Base Paper: Spunlace nonwoven fabric, degradable and flushable materials, wet toilet paper, etc.

Base Paper Grammage: 35-80 g/㎡

Mother Roll Specification: Max W210mm, Φ1200mm, 2×140-210mm (layers×single web width)

Mother Roll Shaft Diameter: 3″ international standard, i.e., 76.2mm

Number of Mother Rolls: 2 twin mother rolls; 1 in operation, the other standby for automatic splicing

Fault Handling: Automatic shutdown and alarm prompt when equipment malfunctions

Material of Parts in Contact with Liquid: SUS304 stainless steel (except belts); liquid adding spray pipe made of SUS316L

Pneumatic Components: Airtac, SMC

Key Bearings: SKF/NSK/TNT

Flat Belts: PU with gem pattern

Synchronous Belts: Gates, Megadyne (Italy), Mitsuboshi (Japan)

Metal Aluminum Foil Tape Detection & Rejection: Automatic detection and rejection of metal aluminum foil tape in nonwoven fabric

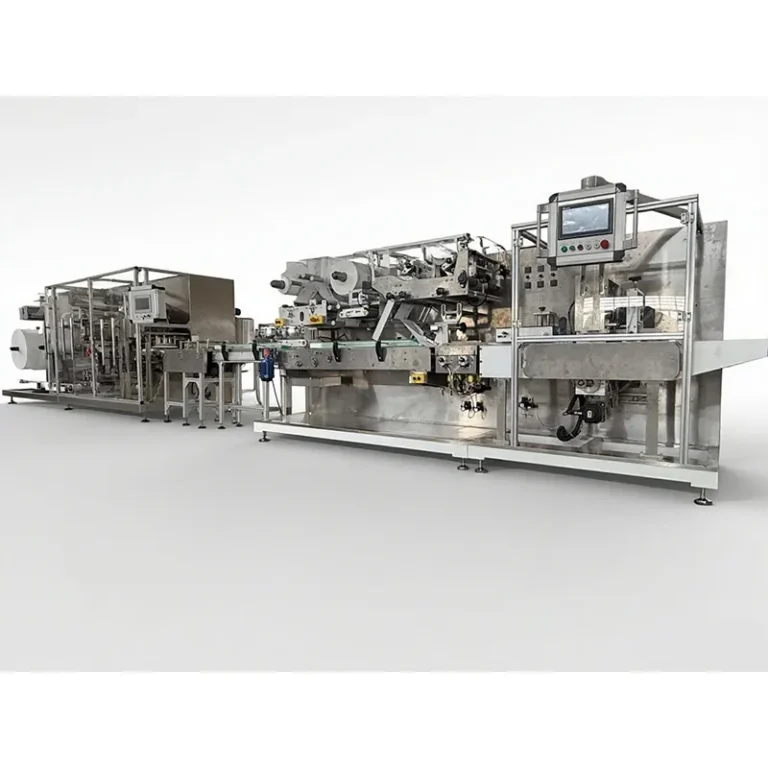

Human-Machine Interface (HMI): Touchscreen

Human-Machine Interface Specification: 10 inches, displays real-time machine speed, with Chinese/English operation platform

Functionality: Production data recording and recipe storage

Software: Maintenance I/O monitoring interface

Product SKU Information Storage: Supports storage of product SKU information

Speed Control: Machine speed can be controlled via HMI operation

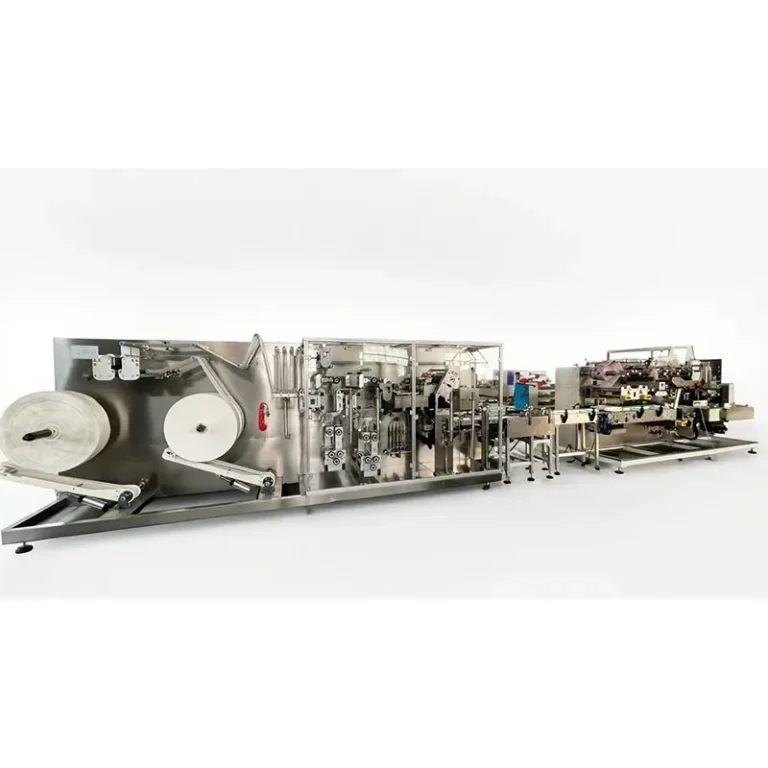

Unwinding Belts: Flat belts with gem-patterned guide strips, food-grade PU

Unwinding Tension Control: Automatic constant tension control

Folding Width: 60-105mm; replace folding plates of different specifications for sizes beyond this range

Folding Style: “Z”-shape, long-tail “Z”-shape; special folding plates required for other styles

Style Switching: Folding style can be adjusted

Traction Control: Servo motor

Traction Conveying Speed: 130 m/min, maximum 140 m/min

Nonwoven Cutting Length: 140-210mm; folded-in-half length 70-105mm

Number of Stacked Sheets: 5-30 sheets (maximum range)

Stacking Height: Maximum 60mm

Folding Speed: Maximum 1200 sheets/min

Cutting Blade Material: Tungsten steel bottom blade

Main Cutting Blade Motor: 3.0KW servo motor

Humidification Range: 2.0-5.0 times; liquid adding amount 20-200g/pack, controlled by flow meter set via screen

Liquid Adding Filter Screen: 240 mesh (61μm)

Liquid Adding Control: Set via LCD screen

Liquid Adding Pipe: Made of SUS316L

Flow Meter: Sanitary-grade glass rotameter, 0-16 L/min

DN8 Medical Silicone Tube: Two liquid adding methods (spraying/soaking)

Vertical Fabric Receiving Drive Method: Servo system

Horizontal Fabric Receiving Drive Method: Servo system

Confluence Drive Method: Variable-speed motor

Fabric Length Adjustment Drive Method: Servo system

Conveying Tension Drive Method: Servo system

High-Pressure Suction Fan: AC380V, 1.1KW

Automatic Rejection of Metal Aluminum Foil Joints: Automatic rejection of metal aluminum foil joints

Drive Method: Servo system

Conveying Method: Baffle synchronous belt conveying, with long/short pitch selection

Material of Parts in Contact with Liquid: SUS304 stainless steel

SUS304 Stainless Steel Mixing Tanks: 2 tanks of 600L each

Tank Material: SUS304 stainless steel

Liquid Adding Pump, Drainage Pump (with Filter), and Tank Transfer Pump: Nanfang Pump CHL20-20

Independent Electrical Cabinet Control System

Total Power: Rated total power of the entire line: 15.0KW

Wire Requirement: National standard copper wire for wet wipe line, 6mm²×5 cores

Total Weight: 7000KG